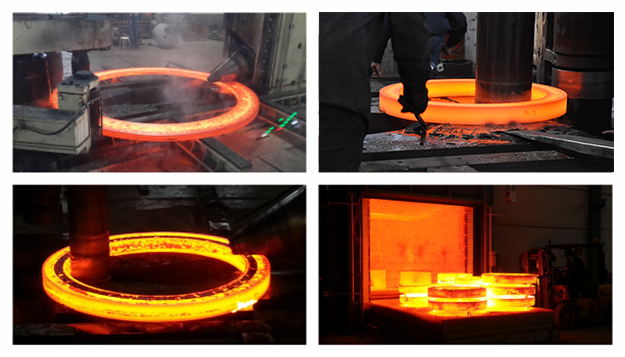

Production of hot rolled ring with rotating process, the cutting-edge technology available in the production of Forged Steel, was firstly started by Gürgenler in Turkey in the year 2013. As a result of the investment made, one-piece weldless steel rings can be produced at a minimum external diameter of 500 mm and maximum heigh of 500 mm. Our company, working with 20 tons per day and with an annual capacity of approximately 6,000 tons, can produce at all kinds of steels (high – low-carbo / chrome – nickel – copper – aluminium alloys / etc.).

As a result of the bidirectional rolling performed on the material at the stage of producion, a homogeneous micro structure is obtaied and equal distribution on molecular colonies is provided. This kind of structure not only increases the resistance of the steel but also prolongs its life.

Its main areas of use are as follows;

• Wind Tower Flanges

• Gears / Bearings

• Steel Rings in the Asphalt and Concrete Plants

• Long Pipe Lines Flanges

• Heavy Equipment Hub Gear

• Valve Bodies

Available steel classes frequently used are as follows;

• 42CrMo4

• S355JR – J0 – J2

• A350 LF2

• 17CrNiMo6

Information of the production capacity is as follows;

• Minimum external diameter: 500 mm

• Highest external diameter: 5000 mm

• Highest externa height: 500 mm